BABA ELECTROPLATERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BABA ELECTROPLATERS

Electroless Nickel Process

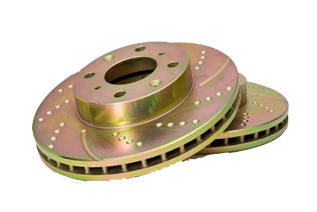

Electroless nickel plating is used in various engineered coating applications: automotive differential pins, brake pistons, slip yokes, oil & gas ball valves, aluminum fuel filters, memory disks, printing rolls, and washers.

Electroless Nickel Provides Endless Coating Solutions:

Corrosion resistance

High phosphorus (over 1,000 hours salt spray resistance)

Wear resistance (rockwell hardness up to 69c)

Low coefficient of thermal expansion

Low thermal conductivity

High melting temperature

Total coating uniformity (consistent tolerances within ± 1 to 2 microns)

Applications & Types

Electroless nickel is a dense, nickel alloy composed of nickel and phosphorus. Phosphorus quantities range from 2% to 14%, depending on the specific application and performance requirements.

Low Phosphorus (2-5%)

2 to 4 % p coatings are microcrystalline and possess high as-plated hardness (620 to 750 hk 100). It is used in applications requiring abrasion and wear resistance.

Lower phosphorus deposits between 1 and 3 % p are also microcrystalline. They are used in electronic applications and provide solderability, bondability, increased electrical conductivity, and resistance to strong alkali solutions.

Mid Phosphorus (5-9%)

Most widely used to meet general wear and corrosion resistance requirements. Commonly used in automotive applications.

High Phosphorus (10-14%)

Commonly used in the oil & gas industry due to superior salt-spray and acid resistance.

Coatings with more than 10 % p have superior salt-spray and acid resistance in a wide range of applications. They are used on beryllium and titanium parts for low stress properties.

Coatings with more than 11.2 % p are not considered ferromagnetic.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.